In an era where sustainable packaging dominates consumer preferences, jute bags have emerged as a top choice for brands and individuals alike. Known as the “golden fiber,” jute transforms from humble plant stalks into sturdy, biodegradable carriers through a blend of age-old techniques and modern factory efficiency. Factories specializing in jute bag production handle everything from raw fiber processing to customized finishing, producing millions of eco-friendly totes annually. This detailed guide explores the intricate factory-based manufacturing journey, highlighting why jute remains a cornerstone of green manufacturing.

From Plantation to Raw Fiber: Initial Preparation

The process begins long before factory gates, but modern facilities often integrate sourcing for quality control. Jute plants thrive in humid regions, reaching 10-15 feet in 4-6 months. Once flowering ends, stalks are manually harvested and bundled.Key factory prep involves retting and extraction. Bundles undergo controlled water immersion in large tanks, where microbial action dissolves pectin binding fibers to woody cores—typically 10-20 days under monitored conditions to prevent over-rotting. Workers then strip fibers by hand or semi-automated beaters, yielding long, glossy strands. These are washed in clean water channels, dried on racks under shaded sheds, and baled for milling. High-volume factories use conveyor systems for faster throughput, ensuring fibers retain natural strength without chemical additives.

Batching and Softening: Preparing for Spinning

Upon arrival at the mill, raw jute enters the batching phase. Fibers are sorted by length, color, and luster using optical scanners and manual grading. Premium grades go to fine bags; coarser ones suit heavy-duty styles.Softening follows in emulsion plants. An oil-water mix (often mineral or vegetable-based) sprays onto piled fibers via spreaders or rollers, making them pliable and reducing breakage. Piling lasts 24-48 hours in climate-controlled rooms. Advanced factories employ automated batching lines with moisture sensors, cutting processing time by 30% while maintaining uniformity—critical for consistent yarn quality.

Carding, Drawing, and Spinning: Creating Yarn

Carding combs fibers into aligned slivers. High-speed breaker and finisher carding machines with pinned rollers remove impurities, producing continuous ribbon-like strands.Drawing frames then blend and elongate slivers through multiple passages, evening out thickness. Spinning twists these into yarn on ring or rotor frames. Factories adjust twist levels: looser for flexible shopping bags, tighter for reinforced handles. Modern plants integrate auto-doffing spindles, yielding 10-20 tons of yarn daily. merger of tradition and tech ensures yarn tensile strength exceeds 200 MPa, far surpassing synthetic alternatives in breathability.

Weaving the Fabric Base

Woven on power looms—shuttleless rapier or air-jet models dominate today’s factories. Warp yarns (vertical) and weft (horizontal) interlace into plain, twill, or herringbone patterns. Density varies: 8-12 oz/sq yard for lightweight totes, up to 20 oz for industrial sacks.Looms operate at 200-400 picks per minute, producing rolls 40-60 inches wide. Inline calendars press fabric for smoothness. Some facilities add lamination here: thin food-grade polymer films extrude onto one or both sides via heated rollers, boosting water resistance without compromising biodegradability. This step transforms plain hessian into versatile bag material ready for customization.

Cutting, Printing, and Customization

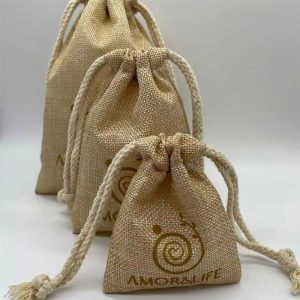

Fabric rolls move to cutting halls. Hydraulic or laser cutters slice patterns based on CAD designs—totes, wine carriers, beach bags. Waste scraps recycle into lower-grade products.Printing employs rotary screen or digital machines with water-based, azo-free inks. Factories offer full-color logos, achieving 1000+ impressions per hour. Heat-transfer or foil stamping adds premium touches. Handles—often braided jute, cotton, or bamboo—pre-form in separate lines.

Sewing and Assembly: Bringing Bags to Life

The heart of bag-making happens in sewing bays. Heavy-duty overlock and double-needle machines join panels, gussets, and bottoms with reinforced cross-stitching. Stress points like corners receive bar-tacking for load-bearing up to 20 kg.Handles attach via X-box stitching for security. Some lines include zipper or magnetic closure integration. Automated folding and turning machines flip bags right-side out, while metal detectors scan for needle breaks. Skilled operators handle 500-800 units per shift, blending precision with speed.

Quality Checks, Finishing, and Packing

Every batch undergoes rigorous inspection: dimensional accuracy, seam strength, print fade tests, and load simulations. Defective units—under 2% in top factories—rework or recycle.Finishing may include anti-mold sprays or UV coatings. Bags fold flat, bale in 500-1000 piece bundles, and wrap in recyclable polypropylene for export. Leading producers achieve zero-waste goals by repurposing trimmings into paper pulp or composites.

Why Factory-Scale Production Matters

Industrial methods have revolutionized jute bag making. Automation reduces labor intensity while scaling output to meet global demand—over 3 billion units yearly. Energy-efficient looms and water-recycling retting tanks slash environmental impact. For bulk buyers, partnering with specialized manufacturers ensures consistent quality and customization.Businesses seeking reliable volumes should explore options from established jute bags wholesale suppliers. They offer MOQs as low as 1000 pieces, diverse styles from laminated shoppers to promotional gift bags, and certifications like GRS or Fair Trade.

The Future of Jute Bag Manufacturing

Innovations like bio-lamination, robotic sewing, and blockchain-traced sourcing are emerging. Blends with recycled cotton or organic dyes push boundaries further. As plastic bans intensify worldwide, factory-produced jute bags stand poised for explosive growth, proving sustainability can scale profitably.Understanding this factory journey reveals why jute bags aren’t just alternatives—they’re superior carriers blending nature’s resilience with industrial ingenuity. Whether for retail branding or daily use, these golden gems deliver durability that lasts years, all while nurturing the planet.