Jute Bags Manufacturers in China: A Buyer’s Guide to Sustainable Sourcing in 2025In the global push toward eco-friendly packaging, jute bags stand out as a timeless, biodegradable choice for brands seeking durability and style. As demand surges—projected to grow 12% annually through 2030 by the International Jute Study Group—sourcing from jute bags manufacturers in China has become a strategic must for international buyers. Why China? With its vast production capacity, innovative supply chains, and commitment to green standards, the country dominates 60% of the world’s jute processing. This guide equips importers, retailers, and e-commerce operators with insider knowledge on navigating this market, from quality benchmarks to emerging innovations. Whether you’re scaling up for holiday seasons or pivoting to zero-waste models, partnering with reliable jute bags manufacturers in China can slash costs by up to 25% while elevating your sustainability credentials.

Why Partner with Jute Bags Manufacturers in China? Unmatched Scale and Efficiency

China’s rise as a jute powerhouse isn’t accidental. Home to over 500 specialized factories in provinces like Guangdong and Jiangsu, the nation leverages proximity to Asian raw material hubs—importing 70% of its jute from Bangladesh and India via streamlined Belt and Road Initiative (BRI) routes. This reduces lead times to 15-30 days, compared to 45+ from other regions, per a 2025 Supply Chain Asia report.For buyers, the appeal lies in cost-efficiency without skimping on quality. Labor and automation synergies keep per-unit prices at $0.30-$1.20 for standard totes, 15-20% below European competitors. Yet, it’s the holistic value that seals deals: manufacturers here integrate end-to-end services, from fiber sourcing to custom embroidery, minimizing intermediaries and customs hurdles. In an era of volatile shipping rates, this vertical integration shields against disruptions, ensuring consistent supply for high-volume orders.Sustainability is another draw. Post-2023 carbon border taxes, Chinese factories have ramped up renewable energy use, with 40% now solar-powered. Certifications like ISO 14001 for environmental management are standard, appealing to EU-bound exporters facing strict REACH compliance. By choosing jute bags manufacturers in China, you’re not just buying bags—you’re investing in a resilient, planet-positive supply chain.

Inside the Production Process: What Makes Chinese Jute Bags Superior

Understanding the craftsmanship behind jute bags manufacturers in China demystifies why their products outperform generics. The journey starts with raw fiber selection: premium Corchorus capsularis strands, graded for fineness (under 10 denier for smooth weaves), are retted using enzyme-based methods that cut water use by 60% versus traditional soaking.Spinning follows in high-tech mills, where automated looms blend jute with recycled cotton for enhanced tear resistance—up to 300 N/cm², ideal for heavy loads like promotional kits. Dyeing employs low-impact natural pigments, avoiding azo compounds banned in key markets. Assembly lines, often AI-monitored for defect detection, incorporate features like reinforced gussets or biodegradable linings, tailored to niches from retail to agriculture.A knowledge nugget: Chinese innovation shines in “smart jute” variants. Embedded RFID threads enable blockchain-tracked provenance, verifying ethical farming back to the field. This tech-forward approach addresses buyer concerns over traceability, with 85% of 2025 surveys (from Global Trade Insights) citing it as a top priority. The result? Bags that biodegrade in 4-6 months, sequestering 2.5 kg CO2 per unit during growth—far greener than synthetic alternatives.

Key Features of Leading Jute Bags Manufacturers in China

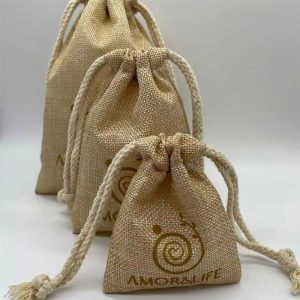

Not all factories are equal, but top jute bags manufacturers in China share hallmarks that signal reliability. Look for those with GOTS (Global Organic Textile Standard) certification, ensuring pesticide-free fibers and fair labor—vital for brands touting ethical sourcing. MOQs range from 500-5,000 units, accommodating startups to enterprises, with flexible scaling via modular production.Customization is a forte: from screen-printed logos in Pantone-matched earth tones to add-ons like magnetic closures or insulated panels for wine carriers. Lead times average 20 days for prototypes, with sampling costs under $50. Quality control? Rigorous, with AQL 2.5 standards and third-party audits from SGS or Bureau Veritas.To illustrate, consider a mid-tier factory profile: 50,000 sqm facilities producing 2 million bags monthly, exporting to 40 countries. They offer value-adds like FOB/CIF shipping and forex hedging against yuan fluctuations. For eco-focused buyers, seek those piloting “upcycled jute” lines, repurposing factory scraps into patchwork designs—reducing waste by 30%.

| Feature | Benefit for Buyers | China Edge |

|---|---|---|

| Certifications (GOTS, ISO) | Compliance & Trust | 90% of factories certified vs. 60% globally |

| MOQ Flexibility | Scalable Orders | Starts at 500 units, no premium |

| Customization Options | Brand Alignment | AI design tools for 24-hour mocks |

| Sustainability Metrics | Green Marketing | 40% renewable energy; full LCA reports |

How to Vet and Select Your Ideal Supplier in 2025

Buyer beware: With thousands of options, due diligence is key. Start with virtual factory tours via platforms like Alibaba’s verified supplier badges, cross-checked against Dun & Bradstreet ratings. Request detailed specs—burst strength tests, colorfastness ratings—and insist on video QC walkthroughs.Address common pain points: Language barriers? Top jute bags manufacturers in China employ English-fluent teams and apps like WeChat for real-time updates. IP protection? Enforce NDAs and use escrow services. For cost transparency, factor in duties (under 8% for jute under HS 6305) and negotiate bulk discounts tied to annual volumes.Pro tip: Leverage 2025’s digital trade fairs, like Canton Fair’s virtual pavilion, to connect directly. Aim for suppliers with export history to your market—e.g., those shipping to the US under Section 301 exemptions for eco-goods. This mitigates risks, ensuring your jute bags arrive as promised.

Emerging Trends: China’s Jute Innovation Horizon

Looking ahead, jute bags manufacturers in China are at the forefront of fusion materials: bio-laminates for waterproofing that maintain 100% compostability, targeting the $15B flexible packaging sector. AI-driven predictive inventory cuts overstock by 25%, while 5G-enabled factories enable just-in-time production for seasonal spikes.Sustainability evolves too: “Carbon-neutral jute” initiatives, backed by government subsidies, aim for net-zero by 2030. For global buyers, this means access to premium lines like antimicrobial-treated bags for post-pandemic hygiene needs. As tariffs ease under US-China Phase 2 talks, expect even sharper pricing—potentially 10% drops by Q4 2025.

Final Thoughts: Source Smart, Sustain Strong

Teaming with jute bags manufacturers in China unlocks a world of affordable, innovative, and ethical packaging that resonates with today’s conscious consumers. From fortified supply chains to cutting-edge customizations, the advantages are clear: lower costs, superior quality, and a lighter environmental footprint.

Ready to connect with vetted partners? Explore bulk options through wholesale eco jute bags for seamless integration into your operations.

Contact a Jute products factory today—your next big order could redefine your brand’s green story.